Air Cooled Heat Exchangers

Finned Tube Air Heat Exchanger

Air Cooler

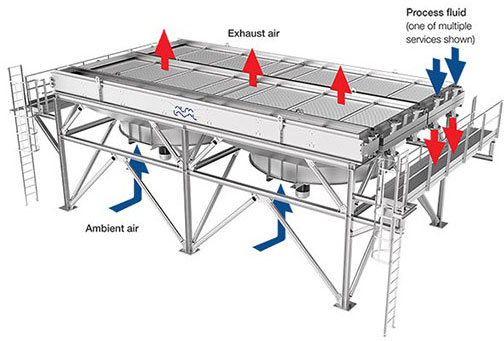

Air-cooled heat exchangers (ACHEs), sometimes called air coolers, are used in refineries, petro-chemical plants, gas treating plants, compressor stations, power plants, and other facilities. ACHEs are used for process cooling and/or condensing. There are thousands of these exchangers in use today, cooling and/or condensing everything from engine jacket water to process steam to highly viscous tar.

Compress Gas Cooler

Benefits

- Customized to your requirements

- Very low energy consumption with Vspeed

- Robust heat exchangers, built for tough duties

- High performance

- Low maintenance requirements

Steam Air Heaters

Main Features

Finned tube heat exchanger type using steam to heat up gaseous media (e.g. air) Customized according to client specification and request (e.g. equippable with air pre-heater recuperator or with optional electrical or oil heater to reach higher temperatures)

Insulated housing (fully welded, sanitary design) and extractable elements Condensate cooling and innovative safety system (see below)

Materials And Characteristic Values

Housing: Stainless steel (AISI 304 or AISI 316) with mineral wool insulation.

Finned tubes: Stainless steel (AISI 304 or AISI 316)

Fins: Aluminum or stainless steel

Discharge temperature: 80 to over 200 °C, depending on steam pressure, or more than 300°C with optional electrical or oil heater

Fin Tube

Finned Tube material:

Tube: Any Kind material of Tube or Seamless Pipe

Fin: Aluminium A 1050; A 1060; AISI 304 or AISI 316 Copper

Fin Type: L; KL; G or Extruded

All Stainless Stell Finned Tube Coil

Use for Food Process or Chemical Process

Tube: AISI 316

Fin: AISI 304 / AISI 316

Air Heater with Thermal Oil as Heating Fluid

Air Heater with Steam as Heating Fluid

Regenerator Air Dryer

Consists of 2 coils, a Cooling coil and a Heating coil. The cooling coil reduce the air temperature and condenses the moisture, while the second coil heats the air to reduce the humidity. Hot and dry air is used in the production process.